Carbon Fiber Inspection with the Phoenix Polarization Camera

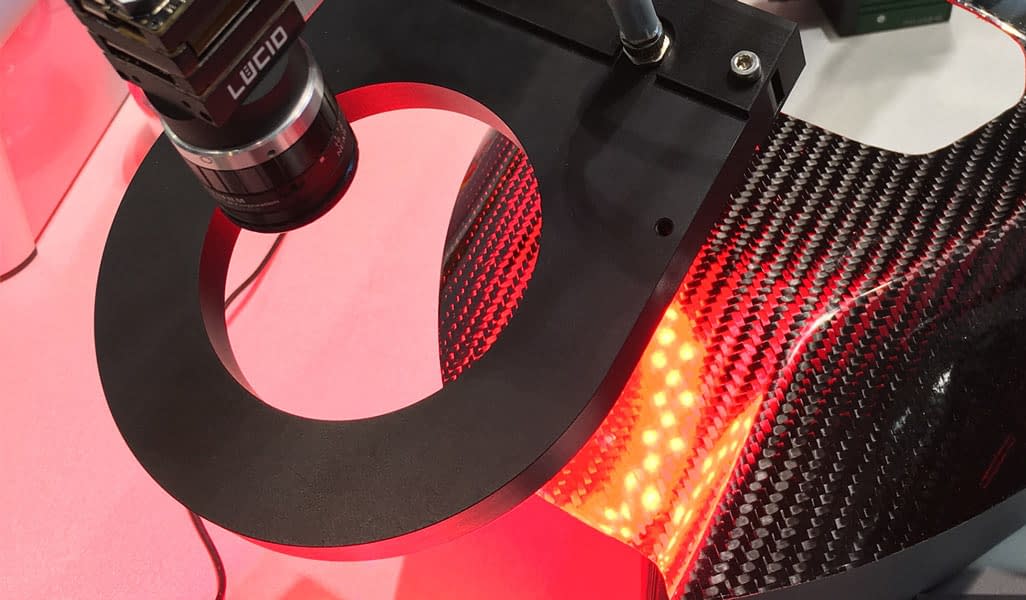

At Control 2018 in Stuttgart, the Fraunhofer Institute for Integrated Circuits IIS showcased a carbon fiber inspection demonstration using LUCID’s Phoenix polarization camera.

One of the unique properties of carbon fibers is that they polarize incidental unpolarized light parallel to the direction of the fiber. This demonstration used the 5 MP Phoenix camera featuring Sony’s IMX250MZR CMOS polarized sensor. The camera captured the orientation and the position of the carbon fiber bundle in real time to determine which way the fiber runs. This is the only way to ensure the required stability of the component.

The new Phoenix polarization camera is used to inspect both dry and finished carbon fibers

Image Copyright Fraunhofer IIS

Above: Unpolarized red light from a commercial ring light shines onto the surface and is reflected as polarized light. The camera measures the angle of the polarization which depends on the fiber orientation.

Image Copyright Fraunhofer IIS

Above: The same setup can also be used for finished carbon fiber reinforced products.

The fibers are visible through the material and the angle of the polarized light is measured.

The 5 MP global shutter sensor with a pixel size of 3.45µm and frame rates of up to 24 fps is based on the popular IMX250 Sony Pregius CMOS mono sensor with polarizing filter added to the pixel. The sensor has four different directional polarizing filters (0°, 90°, 45°, and 135°) on every four pixels. The Phoenix camera is used to record raw data from the camera sensor. The Fraunhofer IIS Polka Imaging software performs the required computation for calculating the degree of linear polarization, which directly indicates the direction of the fibers for each pixel.

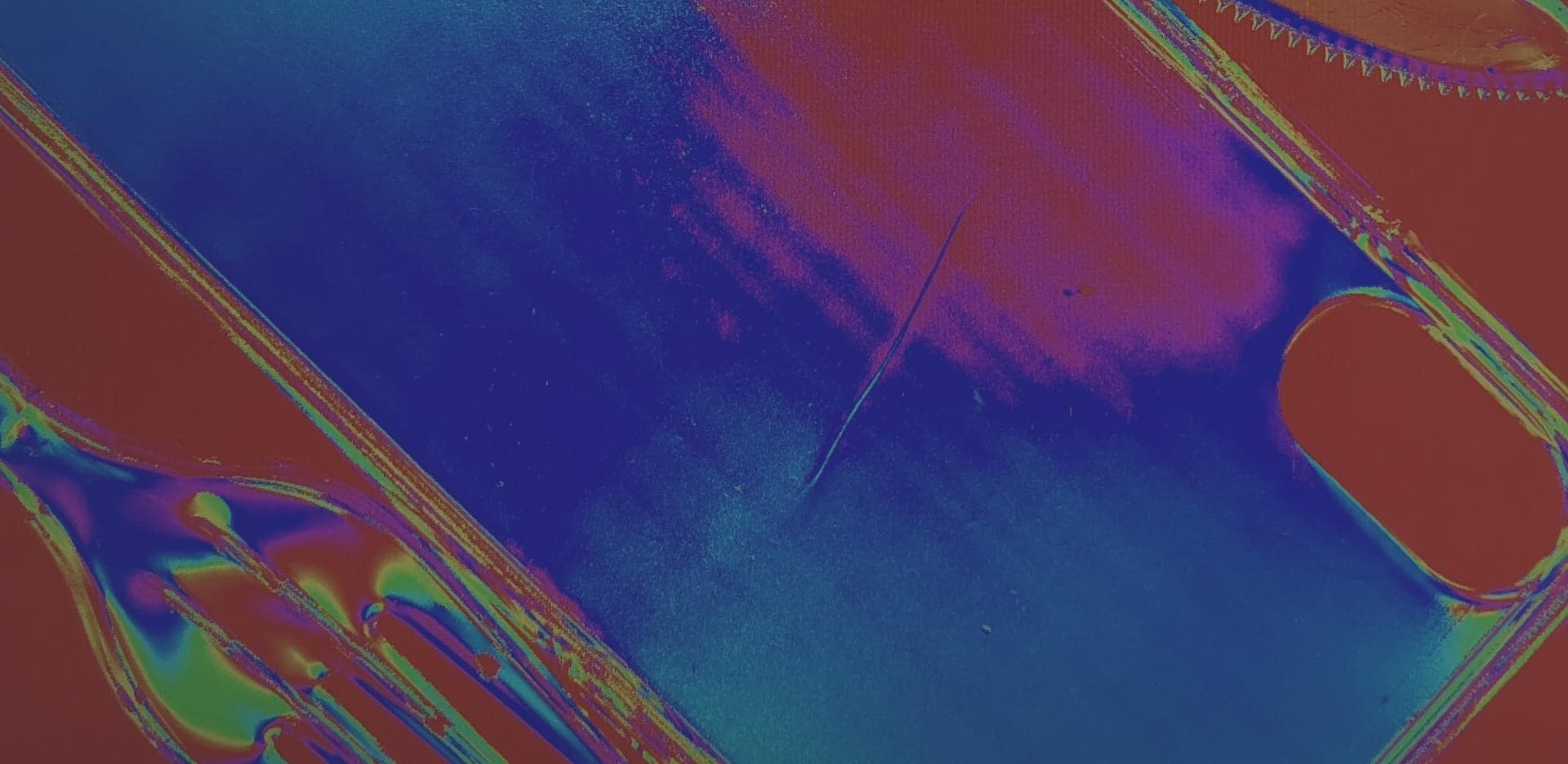

Image Copyright Fraunhofer IIS

The Fraunhofer IIS Polka Imaging software is used as a measuring tool.

The right image shows the measured intensity, the left image shows the false color polarization information, with color depicting of the measured angles of the fibers.

To avoid safety risks, efficient and error-free quality assurance processes are essential in the production of parts made from carbon fiber reinforced polymers (CFRP). Because these components exhibit particularly high tensile strength only in the direction of the fibers, manufacturers have to pay close attention to the direction in which the various plies are formed together during the production process.

Image Copyright Fraunhofer IIS

For glossy and curved surfaces a reflection from the light source can be presented.

The software can detect these areas of the image and indicate that measurements in these areas might be invalid, both in the intensity image (right) and in the false color polarization image (left).

Support Center

Support Center