Overview

With the success of their first Pregius IMX174 sensor, Sony shifted away from traditional CCDs and focused on developing more advanced CMOS sensors. The second generation of Pregius sensors include the 3.2 MP IMX265 and the 5.0 IMX264. Relative to the first generation of Pregius sensors that measured 1/1.2” with 5.86 μm pixel size, the second generation have a smaller ⅔” sensor format with a 3.45 μm pixel size. More impressive, the smaller size allows for compatibility with more cost-effective lenses. As Sony actively improves their rolling shutter CMOS technology in their STARVIS line, the pinnacle of global shutter CMOS performance and value continues to be the Sony Pregius.

As new technologies are introduced each year, Sony continues to push the limits of innovation by improving image quality, increasing frame rates, and adding functionality. Focused on the consumer, Sony keeps each new innovation accessible with reduced costs and intuitive features. Anchored in the ethos of Sony’s Pregius line, Lucid products push the limits of digital imaging while keeping accessibility paramount. To understand the benefits of machine vision cameras that use the Sony Pregius global shutter CMOS sensor, we must first understand the basic building blocks of Sony’s digital imaging technology.

Before Pregius: How Rolling Shutter CMOS Sensors Work

Before Sony released their Pregius global shutter CMOS sensors, their CMOS sensors used rolling shutter technology for sensor readout. Compared to CCDs, CMOS rolling shutter technology provides cost effective high quality imaging and very high frame rates. Unfortunately, if the target or camera is in motion, the images captured display distortion in the form of image wobble, skewing, or banding. This distortion is due to the rolling shutter sensor exposing and reading out pixels one row at a time. A conventional Sony CMOS rolling shutter pipeline is shown below.

Side Note

For applications where high-speed inspection is not critical, rolling shutter CMOS cameras offer an excellent cost effective solution.

Useful in applications such as slow-moving inspection, life sciences, security and surveillance

Above: Conventional Sony CMOS Rolling Shutter Pixel Pipeline.

The above diagram shows a conventional pixel pipeline of a rolling shutter Sony CMOS image sensor. Photoelectric conversion (measured by quantum efficiency) takes place in the photodiode. Electrons are then converted to voltage in the floating diffusion node (voltage is charge (q) over capacitance (C)). The signal then gets converted to a digital signal. It also happens that during this stage the signal goes through 2 stages of correlated double sampling (CDS) to reduce analog and digital noise. This is known as “Dual CDS” and is Sony’s solution to reducing random and fixed pattern noise.

Above: Rolling Shutter Readout with Column Parallel A/D Conversion.

The above diagram is a simplified animation of how conventional Sony rolling shutter CMOS sensors read out image data. Each pixel column uses an independent ADC (Analog to Digital Converter) for high-speed readouts. Each pixel row is exposed to light and the charge is sent for analog to digital conversion one row at a time. It is this row by row exposure that produces image distortion during high speed motion.

Side Note

Sony continues to improve and produce a wide range of CMOS rolling shutter sensors. They include the following family of sensors:

• Exmor

• Exmor R

• Exmor RS

• STARVIS

Sony’s latest line of CMOS rolling shutter sensors – STARVIS – produces exceptional low-light imaging sensitivity.

CMOS Sensors Evolved: Sony Pregius Global Shutter CMOS

To implement global shutter technology into Sony’s CMOS sensors, Sony created an innovative in-pixel analog memory node that sits between the photodiode and floating diffusion node. In Pregius CMOS sensors, all the photodiodes begin exposure at the same time. When the photodiodes complete exposure, the electrons flow into the analog memory and free up the photodiodes for the next exposure. This process is what allows CMOS global shutter functionality. After the charge is transferred to the analog memory, the conversion procedure is the same as rolling shutter sensors. The result is a global shutter CMOS sensor that captures non-distorted images while still utilizing Sony’s dual CDS technology for reduced random and fixed pattern noise.

Above: Sony Pregius CMOS Global Shutter Pixel Pipeline.

The electron charge is quickly transferred from the photodiode to analog memory. Due to their experience in CCD sensor design, Sony was able to develop the analog memory with very low dark current. The memory is shielded and placed within a low dark current area in the pixel structure to reduce dark current shot noise.

Side Note

For the IMX264 and IMX265 CMOS sensors to maintain sensitivity at the smaller 3.45 μm pixel size (compared to previous Pregius sensors with 5.86 μm pixel size) Sony implemented a proprietary pixel condensing process that maintained high dynamic range and high signal to noise ratio.

Above: Sony Pregius Global Shutter Readout.

Thanks to the analog memory, the photodiodes can begin exposure and readout all at the same time. Sony Pregius CMOS sensors not only provide global shutter imaging but also high quality low noise imaging thanks to the continued use of their analog and digital CDS noise reduction technology.

Below: Global Shutter vs. Rolling Shutter Comparison Video

A video example of moving images using global shutter and rolling shutter. Here you can see the image distortion created by rolling shutter (right half).

Low Noise: Sony’s Dual Correlated Double Sampling (Dual CDS)

To reduce noise, Sony CMOS sensors apply CDS to both the analog and digital signal – before and after A/D conversion.

In the analog signal, Sony CMOS sensors use a “reset switch” in each floating diffusion node to drain the accumulated charge of the previous exposure to make room for the next incoming exposure charge. However, some electrons do not drain and end up remaining in floating diffusion. These electrons combine with the next exposure charge, adding noise to the signal. This noise creates an unwanted textured effect on the image called ‘fixed pattern’ noise. Fixed pattern noise is most noticeable in low light imaging but can be successfully reduced using CDS. CDS reduces noise by measuring the leftover charge from the previous exposure and subtracting that from the following charge (which includes both the left-over noise and exposure charge).

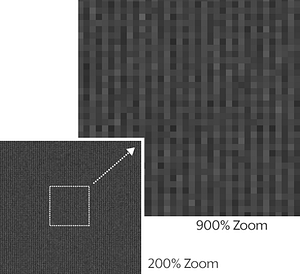

Above: Fixed Pattern Noise (FPN) at 30 dB Gain

Above: Sony Analog CDS Before Column Parallel A/D Conversion.

The noise that is left over from the previous charge is measured and then subtracted from the next exposure charge that mixes with the leftover charge.

Above: Sony Digital CDS After A/D Conversion

Similar to analog CDS the digital signal is read twice, once at the reset level and then again at the signal level. A digital subtraction process cancels out variations between each pixel column resulting in images with minimal noise.

Next Level Imaging Results

Sony Pregius sensors utilize Sony’s latest pixel fabrication technology to offer highly sensitive CMOS sensors. Their low light sensitivity along with high dynamic range allows users to image in dynamically challenging lighting environments. Applications such as autonomous vehicles, informational traffic systems (ITS), or other outdoor environments can benefit from Pregius’ imaging quality. As the lighting changes or the camera enters complex scenes with dark shadows and bright highlights, Pregius sensors will capture more useful imaging data than conventional CMOS sensors, allowing your vision system to make better decisions. In classic machine vision inspection applications, higher sensitivity will allow you to shorten your exposure time and speed up inspection time as well as potentially saving costs on lighting.

| 2nd Generation Pregius Features | Benefits to Users |

|---|---|

| Global shutter | Removes image distortion caused by motion. Allows for high-speed imaging without image wobble, skewing, or light banding. |

| 2/3" and 1/1.8" sensor format with 3.45 µm pixel size | Allows camera to be used with smaller and more cost-effective lenses. |

| High quantum efficiency | Higher sensitivity to light. Benefits low light applications. Allows you to image at shorter exposure times or with less lighting. |

| Very low temporal dark noise | Provides clearer imaging in low light applications. The lower the noise the more one can increase gain / brightness without increasing noise. |

| High signal to noise ratio (SNR) | Higher SNR allows more clarity in your imaging. A higher SNR allows one to reduce imaging time. |

| High dynamic range | High dynamic range allows for better imaging in challenging lighting environments where complex shadows and highlights exist in the same scene. More details will be captured in darker shadows and brighter highlights. |

Summary

Having pioneered CCD development, Sony has applied high quality global shutter technology to their revolutionary CMOS sensors. Moreover, through their circuit and pixel fabrication technologies, Sony has reduced pixel size and increased resolution without suffering any reduction in sensitivity. Current Pregius sensors have higher sensitivity and lower noise than their predecessors. Today’s Pregius sensors enable high picture quality, high resolution, and high-speed imaging without focal plane distortion. These global shutter sensors, when combined with their CDS technology for noise reduction, provide industry leading performance for a wide variety of demanding vision applications. Designed and manufactured with Sony Pregius sensors, Lucid camera technology will continue to deliver unsurpassed versatility rooted in performance and quality.

Pregius and the Pregius logo are trademarks of Sony Corporation.

Support Center

Support Center