Read our Tech Briefs for information on machine vision camera technology and industrial vision technology.

The use of existing CAT 5e and CAT 6 cables combined with the lower power consumption and Power over Ethernet (PoE) has made 2.5GBASE-T and especially 5GBASE-T an attractive alternative for manufacturers of machine vision cameras.

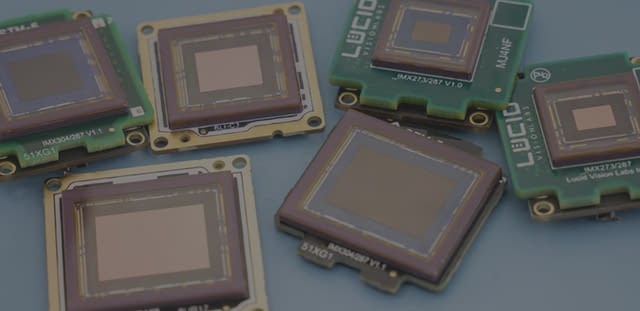

Get clear and sharp imaging in every Triton and Atlas camera, every time. Learn the difference between active and passive alignment and how LUCID uses Active Sensor Alignment during manufacturing to improve camera imaging.

The EMVA 1288 standard makes comparing imaging performance easier. All major camera vendors, including Lucid, measure camera imaging performance using this standard. Learn and compare testing results.

Learn about LUCID’s Factory Tough™ cameras that provide wide operating temperatures, EMC industrial immunity, shock and vibration protection, IP67 protection, and more.

Read about the benefits and new features of the 4th generation Pregius S sensors and how they compare to previous generations. Learn about the strengths of each Sony sensor generation and where Pregius S sensors fit in.

Sony’s 5.4 MP IMX490 CMOS sensor provides true on-sensor high dynamic range and LED flicker mitigation thanks to its sub-pixel technology.

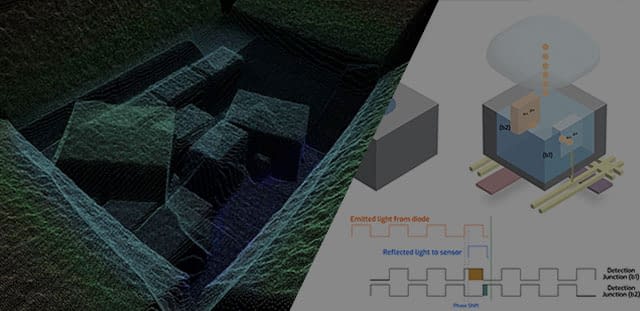

Learn how the combination of advanced technologies such as Sony’s CAPD technology, backside illuminated pixel structure, and LUCID’s specialized camera design, creates the best Time of Flight camera.

Featuring an innovative 4 pixel block design that includes 4 unique angled polarizers, Sony is taking polarized imaging to the next level with a compact 2/3″ global shutter CMOS polarized sensor.

The revolutionary Sony Pregius CMOS sensor is taking sensor performance to the next level. Learn how and why these sensors are improving vision applications.

A combination of lower cost, increased system flexibility, and industry standard adherence has helped Gigabit Ethernet be one of the dominant interfaces in the machine vision world.

While the main goal of TCP and UDP are the same, to send data to devices over a network, there are significant differences on how that data is handled.

Learn why the TFL-mount and TFL lenses are the best option for cameras with sensors larger than 1.1″ up to APS-C size.

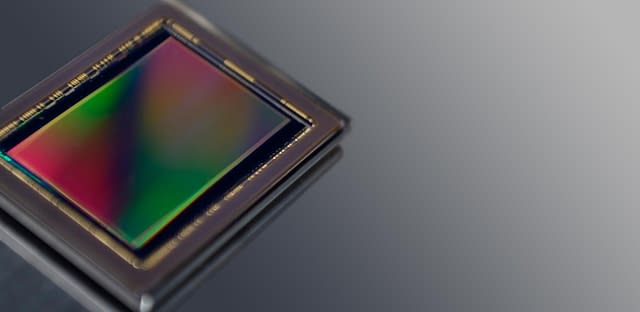

The image sensor is a major component inside a machine vision camera. Learning more about how image sensors work and how they are categorized will help you better choose the right one.

Support Center

Support Center