Showcasing LUCID client stories with our machine vision cameras

Zeabuz has developed an innovative solution for unmanned, zero-emission passenger ferries operating 24/7 in urban areas.

3D perception emerges as a game-changer in spatial awareness thanks to Visionary Machine’s Pandium™

Autonomous Vehicle Integrates Atlas 5GigE Cameras in aUToronto Autodrive Competition

A large warehouse in Spain faced the challenge of efficiently unloading pallets stacked with cardboard boxes of varying sizes and weights with machine automation.

Wood inspection can be challenging because all wooden materials are unique in their characteristics and classification. A high-quality inspection is key to detecting imperfections.

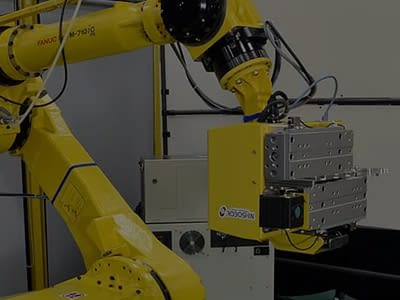

Aiming to improve the versatility of onsite automation systems, Roboshin, a Japanese company focused on robot handling, has commercialized a robot gripper.

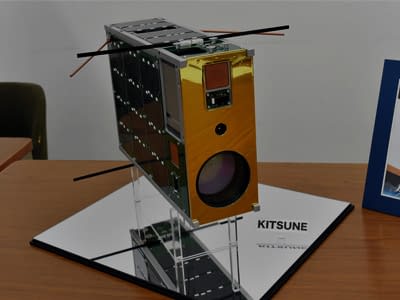

While satellites are becoming more sophisticated, they must meet the ever-growing requirements regarding their size and weight.

Over the years, computer vision combined with image processing technology has become the standard of maritime surveillance.

When IoT data is utilized for real-time construction site monitoring, the image processing can be done in two ways: either on-premises or in the cloud.

When a new pallet tower has been delivered by the forklift, the system detects the new pallet tower and measures the the pallets to determine the specific pallet from 20 different types.

Blister packs are used as unit-dose packaging for consumer goods or small tablets and capsules. To reduce manual labor, an efficient pick and place solution was developed by Pensur.

California-based tech company ADASTEC specializing in autonomous driving software platforms presented their first electric Level-4 Autonomous 8.3 meter bus.

At a cheese factory in the Netherlands, 12 self-driving forklifts have the task to stack and de-stack cheese boxes in a fully automated process, thanks to vision algorithms developed by Florinco.

NUTAI, an engineering service company for industrial automation, has developed a vision system that allows for manual and automatic operation with a collaborative robot, ensuring very precise measurements of drills.

With a true mission to make farming easier and increase productivity, TerraClear is developing an end-to-end automation system which focuses specifically on automating rock removal.

Support Center

Support Center