CASE STUDY

Industry: Manufacturing

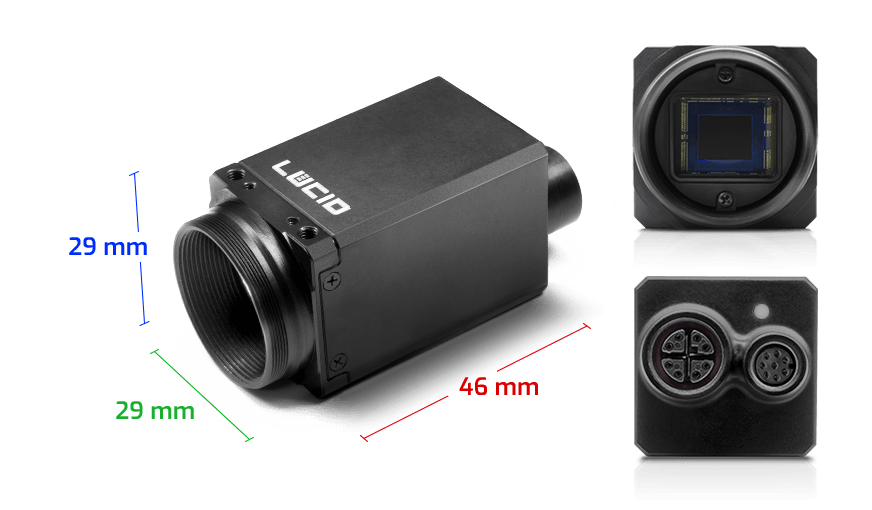

Product: Triton 3.2 MP camera

Application: Inspection

SDK: Custom vision-based AI system

AI Vision System Inspects Concrete Pavers for Defects

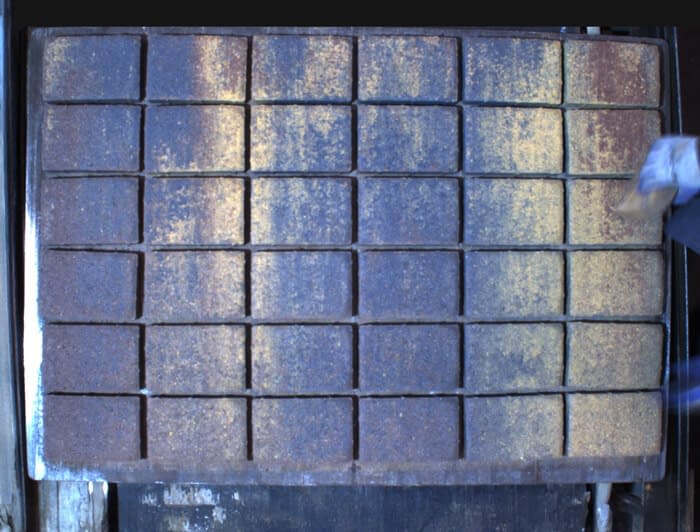

Paver blocks come in various shapes, sizes, colors, and textures, and are widely used in urban infrastructure and residential applications for their durability, aesthetic appeal, and cost-effectiveness. The ability to create customized patterns and designs has made them a popular choice for both public and private spaces.

Pavers are produced in plants across the country, located near customers to reduce transportation costs. Manufacturing takes up to three days, requires skilled labor, and carries significant utility expenses. Defect rates around 1-2 percent are typical.

Challenge

Quality inspection of paver blocks is usually performed by human operators who rely on visual judgment to spot surface flaws such as clay balls, cracks, and chips, or to spot missing pavers or foreign objects on the board.

In addition to being costly, this process is inconsistent across operators, shifts, lines and plants. Smaller defects are frequently overlooked, especially when larger flaws are present. Standards vary between shifts, and visual fatigue reduces performance over the course of a shift.

Faced with increasing demand for quality, a major US paver manufacturer wanted an inspection solution that could keep pace with production, eliminate subjective variation, detect and classify defects, and integrate seamlessly with existing systems—all while being affordable and scalable across multiple facilities.

Solution

To address these challenges, the manufacturer partnered with Accella AI, a provider of AI-based solutions, located in Sunnyvale, CA, to implement a proof-of-concept using the Accella MFG Bot™, a vision-based AI system designed specifically for real-world shop floor applications.

Installed on the dry side of the lines , the system combines a high-resolution LUCID Triton® 3.2 MP color camera with a deep learning model trained to detect and classify defects in real-time. The Triton camera is well suited for a rugged industrial environment, featuring Sony’s IMX265 CMOS sensor, a Factory Tough® design with IP67 protection, Power over Ethernet (PoE+), and M12/M8 Ethernet connectors.

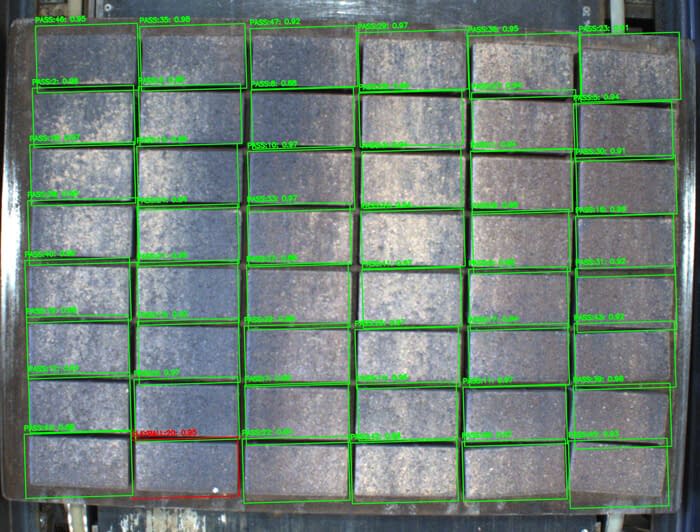

The inspection process works as follows: the Triton camera, mounted overhead, is triggered by the production line’s PLC to capture every board of pavers as it moves through the station. First, the AI identifies each paver on the board; then it assesses them for defects. Results are displayed on an operator screen, with the defective pavers highlighted so the operator can remove them from production.

The AI model quickly achieves the required accuracy for defect detection and with continued learning during normal operation an accuracy up to 99% can be achieved. The total inspection time per board remains under 1 second, leaving headroom to add additional features such as color or height measurements in the future. The system processes every board, flags each defective paver, and additionally is capable of monitoring operator activity to determine whether and how quickly defects are addressed.

What sets the solution apart is not just its speed or accuracy, but its consistency. Unlike human inspectors, AI applies the same quality criteria to every product, regardless of shift or surrounding context. It also adapts quickly to new data, learns from edge cases and updates its detection models without needing complex reprogramming. Integration with PLCs is seamless, and the system is designed to connect with MES and ERP systems during rollout.

By using affordable, off-the-shelf hardware and modular software, the solution is both cost-effective and scalable. It requires no specialized input from operators and can be replicated across other stations and facilities with minimal reconfiguration.

Conclusion

The proof-of-concept demonstrated that AI-based visual inspection using LUCID cameras is not only feasible but highly effective in paver manufacturing. It outperforms manual inspections in speed, reliability, and consistency while also providing valuable insights into operator behavior and process efficiency.

To learn more visit:

Accella AI

Triton® camera product page