CASE STUDY

Industry: Agriculture

Product: Helios2+ 3D Camera

Application: Automated Cow Cleaning

SDK: Cognex Designer & Deep Learning Studio, Arena SDK

Automating Dairy Farm Hygiene with 3D Vision and Robotics

Dairy farms are faced daily with challenges to automate labor-intensive processes in milk production, particularly pre-milking udder and teat cleaning. Consistent sanitation is not only a legal requirement but also a critical factor in animal health and milk quality. Manual cleaning methods are prone to variability, and existing mechanical scrubbers have struggled to provide consistency across different farms and animal conditions. To solve this, Fisher Smith, a UK-based machine vision system integrator, developed a robotic system capable of automatically cleaning each cow before milking. Cows are brought onto a rotating milking carousel, where the system identifies the udder region, performs the cleaning process, and then applies the milking apparatus in a fully automated workflow.

Challenge

Designing a system that could reliably and safely clean cows in a commercial farm environment required overcoming several obstacles. The barn presented harsh and variable environmental conditions, with dust, moisture, and organic matter necessitating a ruggedized camera housing and an automated lens cleaning station. Accuracy was another major hurdle: the robotic cleaning arm needed precise positional guidance to interact with a living animal without causing harm or discomfort. This required a robust robot-to-camera calibration and datum alignment to ensure positional certainty and repeatability.

The image processing demands were equally challenging. The application needed to process complex 3D data, including X, Y, Z, and intensity images, fast enough to keep pace with the movement of the carousel and the robot. A custom deep learning pipeline had to be built to reliably distinguish teats from other anatomical features such as tails or background elements, all within a narrow processing time window. These challenges highlighted the limitations of existing mechanical or manual cleaning systems, which were inconsistent, difficult to scale, and unable to guarantee compliance with hygiene regulations.

Solution

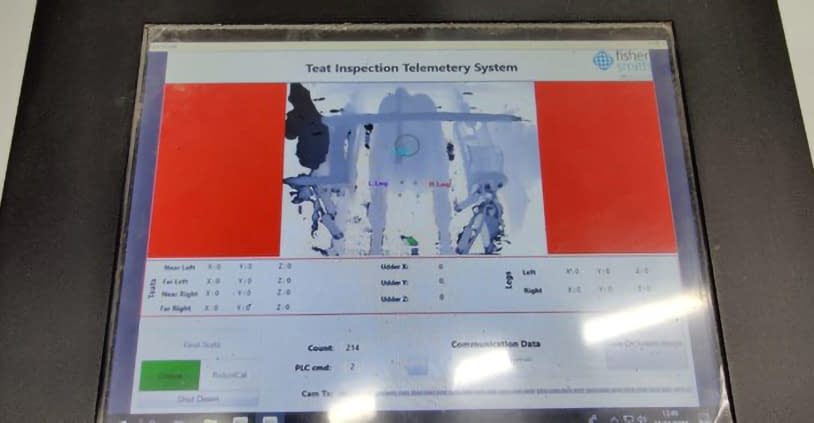

LUCID’s Helios2+ Time-of-Flight (ToF) camera, supplied by ClearView Imaging, LUCID’s authorized distribution partner in the UK, formed the foundation for solving these challenges. The camera’s IP67-rated housing, combined with high dynamic range (HDR) and high-speed operating modes, made it ideal for the demanding farm environment. Its ability to generate accurate 3D depth images of the cow’s underside allowed Fisher Smith to build a reliable deep learning inspection pipeline. Using multiple XYZ map outputs, the Helios2+ delivered detailed spatial data that was processed within Cognex Designer and Cognex Deep Learning Studio to identify teat locations with high confidence.

To integrate the camera seamlessly, Fisher Smith developed a custom dynamic link library (DLL) that enabled smooth communication with the Cognex Designer and Deep Learning platforms. LUCID’s ArenaView software was used to configure camera profiles and optimize depth accuracy. The Helios2+ was connected via GigE Vision to a PC, ensuring fast and stable image transfer. Once processed, the data guided a six-axis robot to position its cleaning tool precisely on each teat, achieving thorough and repeatable results.

The system provided accurate, real-time 3D data for robotic control, met legal hygiene requirements, and significantly reduced manual labor. Moreover, the deep learning model proved transferable and adaptable, meaning the system could be deployed at other farms with minimal retraining. The integration of LUCID’s Helios2+ camera transformed what had previously been an inconsistent process into a precise, automated, and scalable solution.

What sets the solution apart is not just its speed or accuracy, but its consistency. Unlike human inspectors, AI applies the same quality criteria to every product, regardless of shift or surrounding context. It also adapts quickly to new data, learns from edge cases and updates its detection models without needing complex reprogramming. Integration with PLCs is seamless, and the system is designed to connect with MES and ERP systems during rollout.

By using affordable, off-the-shelf hardware and modular software, the solution is both cost-effective and scalable. It requires no specialized input from operators and can be replicated across other stations and facilities with minimal reconfiguration.

Conclusion

By combining robotics, AI, and 3D vision, the dairy farm equipment provider successfully addressed a longstanding challenge in livestock automation. The Helios2+ enabled the system to deliver accuracy, robustness, and repeatability required to clean cows effectively and consistently. Beyond compliance with hygiene regulations, the solution reduces labor costs, increases throughput, and improves overall animal welfare. Its adaptability across multiple farms positions it as a scalable approach to modern dairy automation. This case demonstrates how industrial-grade 3D vision technology from LUCID working in harmony with the experts from Fisher Smith can play a pivotal role in bringing precision robotics and AI to agriculture.

The Helios2+ Time-of-Flight camera, with IP67 protection, allows the system to accurately and safely clean the cows in a commercial farm environment.

To learn more visit:

Fisher Smith (Machine Vision System Integrator)

ClearView Imaging (LUCID’s Distribution Partner in UK)

Helios2+ ToF Camera Product Page